When the sun is close to the horizon Solar PV Panels generate less energy than when the sun is directly over the Solar Panel.

The reason for this is that the sun’s rays pass through more of the atmosphere thus reducing the sun’s energy (photon energy) on the PV panel. If it is an overcast day they will produce less energy. To translate this into numbers- in the winter when the sun is low in the sky (say 14 degrees from the horizon ) the total irradiance from the sun measures around 780 W/m2 (watts per meter square) with a clear sky. In the summer one would expect to see 1100 W/m2 (55 degrees from the horizon). The bottom line is that if one can point the solar panels perpendicular to the sun one will get a higher electrical output kw/h.

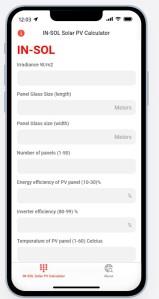

In order for consumers to purchase and compare solar PV panels manufacturers have agreed a way to compare the output power of Solar PV panels and this test is referred to as Standard Test Conditions (STC) . The test is done at an irradiance of 1000w/m2, at a air mass of 1.5 (approximately 42 degrees from the horizon) and at a temperature of 25 degrees. The value w/m2 is how solar irradiance is measured while the PV panel output power is measured in watts. The following calculator will help you understand how the output power of your PV System (in watts) is affected by solar irradiance and other factors. Check your Solar PV Output Power in watts.

Most roofs have a pitch of around 35 degrees. The best direction to point the solar panels is usually south but with some solar PV installations, it is possible to have some pointing South and others pointing West in order to collect as much energy as possible during the summer. Meters used to measure solar irradiance are called pyranometers, Solar irradiance meters, or solar radiation meters. An example of how these meters are used to locate, measure, and check if your Solar PV system is working efficiently is shown below. The calculator above can be used with these meters.

PV Panel Shading

A factor that has a significant impact on the output power of a PV System is shading on an individual Solar PV panel. This can take the form of chimneys, trees or other houses. The reason for this is that if one examines each solar panel one will see that it is made up of individual cells wired together in series to make up a full solar panel (see below). If one or more cells are shaded when installing a traditional solar PV system (One inverter) the output power is reduced for the whole system. There are other solar PV systems that use microinverter’s or DC optimizers that will not be seriously impacted by shading thus the consumer will generate more electricity.

Another factor that significantly reduces the solar panel output power generated is the panel temperature. We are lucky in Ireland to have a mild climate with day temperatures not usually going above 20 degrees (on a good day). What this means from a practical perspective is that a solar panel in Ireland will generate more power than a solar panel in Spain on a cloudless day.

Solar PV Components.

The components that typically make up a solar PV system are PV rails which support the PV panel , roof brackets/hooks that connect the rail to the standard tile or slate roof and clamps that connect directly to a specified roof types such as zinc or steel roofs. There are separate pv panel mounting systems for flat roofs or ground mounting. If one wants to explore PV mounting system suppliers -use a google search for “roof mounting systems for solar panels“. As I used a zinc roof one must ensure expansion joints are installed in the pv rail every 3 meters.

PV Panel Types

There are three types of PV panel cells -monocrystalline (these aesthetically have an even black finish –shown above), Polycrystalline which have an uneven shade of blue crystal cells and CIS types. Monocrystalline are more common and are slightly more expensive than polycrystalline and CIS are now more difficult to purchase (shown in part 1 of the blog). The options available when selecting PV panels other than the type above are length of equipment warranty and length of manufactures performance warranty. The majority of PV panels generate DC (direct current). All PV panels must be angled at least 3 degrees from the horizontal. PV panels produce DC power and to give you an idea of what 4 panels can produce and the energy they can generate for a load, loose connections or cable damage please see this video .

Inverter Options

Inverters are principally available in 3 types -one central inverter for a full PV installation without battery charging, a central inverter that has inbuilt battery charging facility and micro inverters for individual panels or a pair of PV panels.

Central inverters. The important factor here is the warranty length and how many MPPT (maximum power point tracking) channels does the inverter have. If one was installing 8 panels in two rows (strings), two separate MPPT channels would mean that the two rows of 4 panels would have their own ability to generate power independently of the other row (string) so for example if one row of pv panels got dirtier/shaded or a fault occurred on one panel the other row would keep generating at full power. As all PV panels are not exactly the same the separate MPPT channels allow for a higher output yield . When selecting an inverter one must match the PV Panels to a particular Inverter. Once this is done adding more panels can become restrictive and may mean that one needs to change the inverter again. If the inverter fails the whole system fails. If one needs to change a PV panel in the future the central inverter may also need to be changed.

Micro Inverters-simplify the installation of a PV system and permit simple expansion. It is really close to plug and play . Because they are paired with a PV panel they manage shading better than a central inverter. The voltage generated is also different to the central inverter in that it produces low voltage AC -the same voltage as all domestic appliances like fridges, washing machines etc. There is also less of a chance of fires because of loose connections/damaged cables. They offer full management of your PV system with apps and individual panel performance monitoring. Pv panels must also be matched with the individual inverter using the PV panel data sheet. This is one such calculator.

Batteries

As stated before I personally am not in favour of using batteries for PV panel installations. The reason is that batteries are expensive, they are another failure point and I feel they are needed for vehicles more than PV installations. For example, a 300 litre water tank can store 20kw of energy at 60 degrees (a stainless steel water tank would cost around €1000-while a similar battery could cost €10,000 to €15,000 and still would need to be replaced after approximately 6000 cycles). All homes need hot water thus sending any excess electricity from the PV panels could be fed to a hot water tank. So instead of adding batteries why not consider changing the hot water tank and place elements at the bottom of the tank and the middle of the tank.

Another good idea is to switch to night time electricity which currently is half the price of the day unit to supplement the lack of PV power during the winter to heat the water tank.

My preference is to install a side arm heat exchanger to the water tank so that I can achieve better hot water stratification. Stratification is the creation of layers of hot water free from movement/mixing when one heats water. What happens for example is when cold water enters the tank at the bottom it can mix the stratified layers of hot water thus reducing the water temperature. It is difficult in Ireland to purchase water storage tanks that have simple devices fitted that maximise stratification with devices such as an inlet baffle on the cold water inlet .

To complement the above use of a water tank one can add a single shower pump and feed all showers from the tank.

The above will reduce the use of electric showers which are the highest electrical energy consumption devices in a home. From personal experience, I can say that 150 litres of hot water (half a 300 litre tank) can provide 6 showers a day. Currently, I use off-peak electricity to heat half the tank.

If you are a new build one can plan to install the shower pump outside the house in an insulated chamber below ground level near the tank. This is what I have done to reduce the noise as we have a single-story home.

In part 2b we will look at how to analyze Solar PV quotations.