Factory Built or Site Construction

There are many options today when deciding to build. One can use a factory built design or use traditional block work or timber frame on site. Some factory built designs are as follows by way of example http://www.scanhome.ie . One can select the level of input oneself such as only construct the frame and say the self builder can do the rest or let the builder/supplier do everything.

How much Work does a self builder take on.

As a self builder I would try and get the foundation, frame, roof and windows installed then one can work in the dry to finish it. One is left with indoor wall completion, plastering , air tightness, Heat recovery, Wiring, Plumbing, Rain Water Harvesting, House heating System, Water heating system, floor finish, Painting, furniture , kitchen more than enough work for the self builder. The above need to be well thought out before laying the foundation or erecting the frame and the finish design of the roof.

The Building Standards-Self Build

One needs to comply with the building regulations. Always remember these are the minimum standard. It is always better to go for a home that will last well into the future that is warm and supplies fresh air. A lot of new homes built today are of a poor standard and this can be seen in the UK and Ireland. See example https://energysaveguy.tumblr.com.

The Sales Pitch

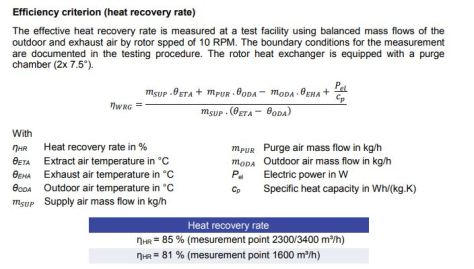

There are buildings that can receive different rating systems such as LEED and BREEAM. A good video on the good, the bad and the ugly of these can be seen here. They focus on equipment and energy accessories so it is best to leave these and focus on the basics. What are the basics –Insulation, Air-tightness, Windows, Heat Recovery (fresh air supply), and minimising thermal bridging (heat loss through details on the build). When one does the above one finds that the heating system is simple, the house costs very little to run and is healthy if the correct materials are selected and installed in correct sequence during the build.

The Gold Standard-Passive House

The highest energy standard to build a house , an apartment, school or commercial buildings is the passive house standard. It focuses on the basics and uses physics rather than rating systems to design the building. All the calculations are done before the house is built on a passive house planning software package (PHPP) which takes into account for example how much solar heat the glass in the window will leave into the house, how much heat will be lost through the glass from the inside to outside, how much heat is lost through the frame, and the heat lost on how the window is installed in the wall. Every building detail physics are analysised to ensure that one ends up with a comfortable home.