Mounting of HRV Unit

Different HRV units have different mounting options. Some are floor only, wall only or ceiling or all three. Some units like the Airflow DV145 that I purchased can be mounted on the floor or wall while smaller Airflow units can be mounted on the ceiling, floor or wall. One needs to make sure that there is space underneath for the condensing water outlet. If the unit is mounted on a wall make sure that vibrations do not interfere with noise sensitive rooms such as bedrooms. I mounted ours on a sound proof and isolated base and used other sound proof methods to isolate it from an adjacent room.

In the early stages of the build the fresh air inlet and stale air duct positions were selected with a spacing of over 2 metres. If the supply and exhaust ducts are too close this can interfere with the correct operation of the HRV unit. This entailed finding an HRV unit that would be flexible in the options available to simplify the space required for the main ducts and keep the runs as short as possible. The lengths of the supply and exhaust ducts play a big factor in the efficiency of the whole system. The Airflow unit comes in a right hand and left hand model. I found that different manufacturers have different duct layouts even though they have Right Hand and Left Hand models.

DATA from the HRV with the Post Heater On

One can see from the above graph that with the winter sun I needed to switch off the heater and switch to summer bypass as the weather improved. The next plan is to automate the bypass mode when the solar irradiance level measured in W/m2 and temperature exceed a set value then the HRV would automatically switch over to the summer bypass mode as one is gaining solar heat. Update-2022-We found it easier and more economical to switch of the post heater permanently and set a base heating load of 1.35kw (200m house floor area) for the winter and manually switch on a 600 watt electric oil heater for days or evenings when the solar gain did not happen. In this way there will be days when one is not in the house and it is proving to be effective also. Also as the house id energy efficient the room heats up quickly.

HRV Soundproofing

As the internal fans are to the rear of the unit I added a small amount of soundproofing as an experiment. I was able to reduce the db level from 49 db to 44 db. Each 3 db approximately equates to twice as loud or twice as quite depending on whether you are increasing or decreasing the level.

I mounted the unit in the hallway entrance so extra sound proofing was required. If one has a utility room then extra sound proofing would not be necessary I feel.

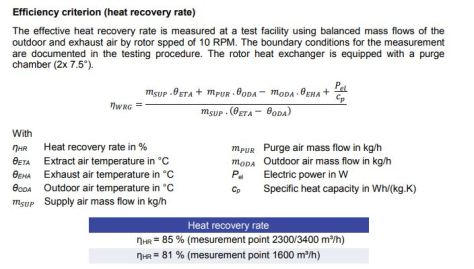

HRV Efficiency

Following on from the previous blog I had a display panel built that calculates the HRV efficiency using the supply method and extract method by means of the Modbus data connection available in the HRV unit . In the Image below one can see S100 (Supply method for calculating efficiency) and the E 90 (Extract method ) as a percentage. The supply method is the one typically used by manufacturers in brochures. The D displays the difference .

The top line displays the temperatures of the Inside air and the air leaving the house followed by the Outside air temperature and the supply air temperature to the house. When the post heater is on the efficiency calculated with the supply method sometimes displays a number greater than 100% as the heater is built into the unit and mounted before the thermostat. The extract method for calculating the efficiency is a closer representation of the real efficiency and it is similar to the passive house method (uses the same principle ). The extract method does not use the supply air temperature in the formulae.

Access for repair and maintenance.

Some HRV units require side panel access so ensure that you have enough space to get access to fans/ filters for cleaning and maintenance . The Airflow DV145 can be fully maintained from the front cover so it can be fitted in a corner space without restricting future access to internal parts. The filters are also maintained from the front panel.

Functions and Benefits

When selecting a unit- what was important to me that there was an integrated summer bypass function in the unit, software control by a smartphone with data capture (a manual control panel-is an extra cost and another item that could fail) and an integrated post electric heater. Airflow also sell a ground source heat pump option connection to the HRV which I did not purchase. For those installing a stove / fireplace one requires a Fireplace function built into the HRV . The Airflow DV145 has this function.

September 2018 performance.

Summer Bypass

The summer bypass function allows one to bypass the heat recovery function during warm weather or reduce winter sun peaks (when the sun is low on the horizon). The way this works is to bring the air outside directly through the ducts in order to reduce the internal temperature at night or during the day. One can see from the image above on the 28 and 29th of September I forced the HRV unit to summer bypass during the day to keep the temperate under control with the winter sun. No heating had been switched on for the month of September and the night temperature outside has hit the lowest in the same month of 2 degrees.

The Airflow unit is software controlled by means of your phone or your personal computer . This helps keep the HRV cost down, gives remote control and it provides data for analysis. The physical manual control panels in general cost €200 or more.

The post heater in the Airflow DV145 unit has a PWM (pulse width modulation) heating element control which means that it can control the switching of the heater within a fine tolerance for heating the air rather than just switching the heater On and Off. The reason I installed this was really to provide a back up option to the main house heating system (approximately €200 extra).

House Heating System

The house heating is currently designed around two storage heaters of 1.7 kw each to heat the house using off peak electricity and operate for 7 hours a day. I picked up one unit for free and the other unit cost €70. I suppose one could say that the total capital cost of the heating system was €270 when one adds the HRV post heater.

For the month of October one of these heaters was switched on for 14 days. The post heater also improves the frost protection functionality within the HRV and helps maintain a heating level of 21 degrees Celsius throughout the house.

Below is an example of how the HRV switches on different heating loads in the post heater while maintaining a set temperature . The time interval below is over 60 seconds (full screen view) and the heater appears to adjust the power output required continuously to maintain the set temperature.

Duct work for primary supply and extract

I selected an insulated 210mm EPS duct for the extract pipe as this duct carries the coldest air from the HRV unit .

Supply and Connecting Manifold Ducts

There are a number of options. My understanding is that the larger duct systems such as 150mm feeding multiple rooms with silencers is the best option if one can accommodate this in the build early on and find a good designer. I opted for the 91mm semi rigid ducts using a manifold system from https://www.fraenkische.com and I am very happy with the low noise level and amount of air being delivered throughout the house. I use a co2 sensor to monitor how the flow rates are working in different rooms.

Hiding Ductwork

When one is designing a house to the passive house standard or installing an HRV unit in an energy efficient /airtight house one can reduce the cost on the system if one plans the service routes of the ducts early on and selects particular joist types. It is expensive to batten and counter batten to hide the ducts afterwards as one needs to try and keep the duct-work within the airtight envelope.

I opted for the manifold system using the largest semi rigid ducts I could find. These were the Fraenkische-profi-air classic pipe with an internal diameter of 78mm and outside diameter of 91mm. The larger the duct the lower the air friction and noise when delivering air to rooms such as bedrooms. These ducts are also anti-static and low emission.

Below are the choices I came across from the semi rigid range. The white duct is made by Fraenkische.

Connection ducts from Manifold to HRV.

For the ducts that connect between the main HRV unit and the manifold I used an insulated flexible sound reducing duct (as seen below). This is made up of an inner foil with sound reducing properties, next an airtight plastic membrane and then insulation followed by another layer of foil. The inner rim is re-enforced with a steel wire to provide rigidity. It is time consuming connecting this up but it appears to have done its job.

Contact Details: seamus.sheehy.selfbuild@gmail.com