Temperature Recordings

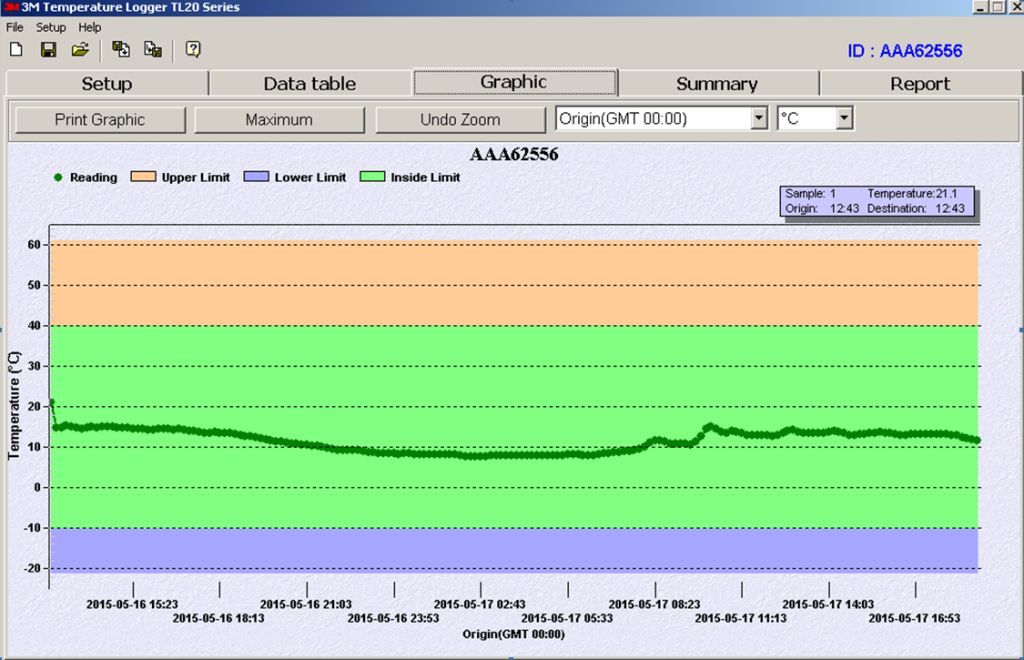

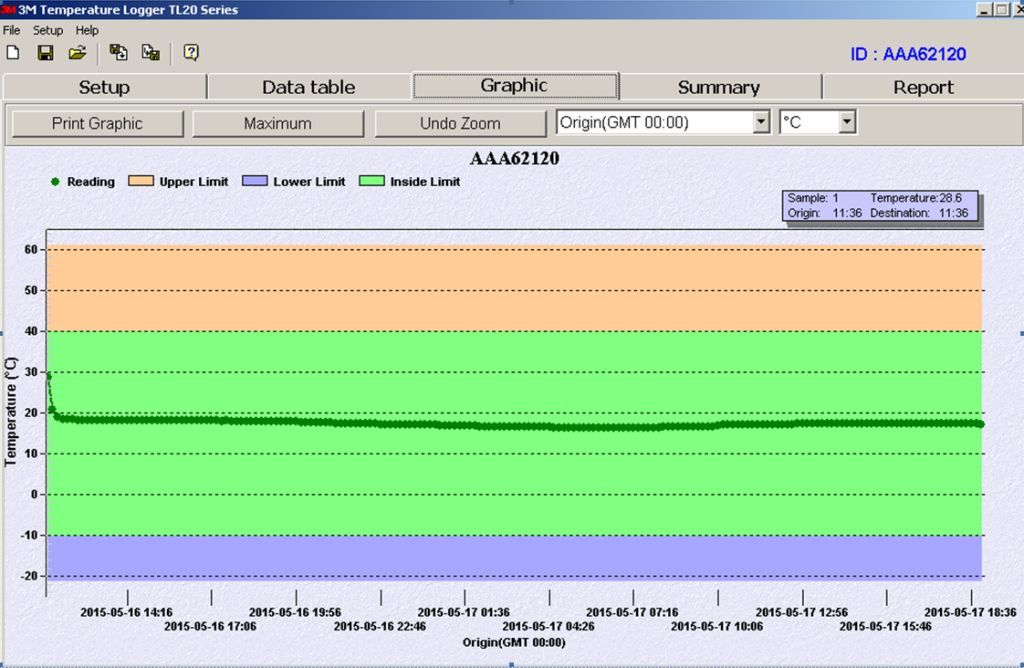

I decided to record the temperature inside and outside in order to get a feel for how the house performs before it is finished.

The current state of the self build is :

- Two ceilings have an airtight membrane and one of the walls has a membrane (both are incomplete)

- I still need to install another 50 mm of insulation on most of the internal walls (2 of the 8 walls have the 50 mm insulation.

- Two windows are not sealed and all have no airtight membranes attached.

- The lower windows are shaded by scaffolding (minimum solar gain at the moment)

- The HRV inlet and outlet ducts are loosely taped over

- The floor is concrete

- The wall and glue-lam beam wood moisture level is 13.5%

- There is no heating system

I collected data over a similar time period to the above and the results were similar.

The Old Plan and the New Plan

The plan was to install another 100 mm of insulation on the internal walls but I have now decided to not do this based on the results above and adjustment of the PHPP (passive house planning package) software. I feel I have left enough of a safety margin in the PHPP to still attain the passive house standard. For example I left the ground level door and window installation thermal bridge psi values at the PHPP default .

Installing the extra insulation would cost €1500 and the wooden frame to hold it in place would have added another €2000 approximately (Savings €3500) . I also reviewed the ceiling voids as I had planned to allow a 100 mm service cavity for the HRV ductwork. This was on reflection going to cost an extra €3500 approximately but now I will be able to hide the ducts using a simpler localised approach (Saved another €3500). It is nice to be in a position to review the costs at the pace of our self build.

Data Logging and Monitoring

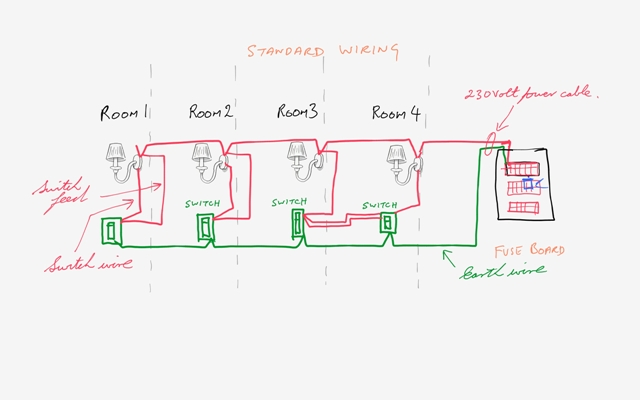

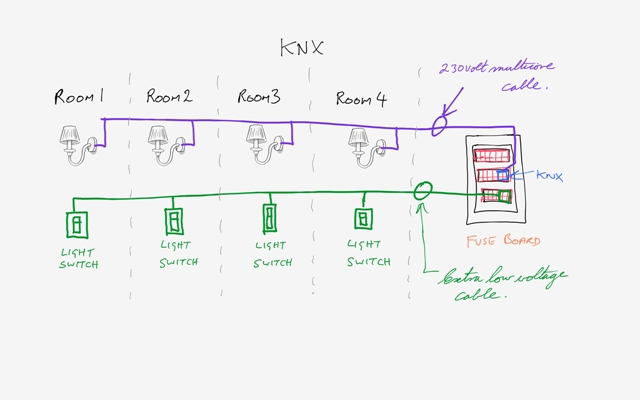

I am now researching an economical building performance monitoring and control system that will record and display data over a longer period of time and allow me to control certain functions such as entrance gates, lighting etc . I have read that the actual performance of houses being built whether passive or standard do not always perform the way they were supposed to.

I feel the only way to monitor this is to have an economical simple system (easy to use ) that watches for failures and highlights issues during the life of the build. When one reduces the energy levels to a very low level finding problems before they increase cost is a must. For example on a recent school project the storage heating contactor went faulty in the closed position which meant the storage heating was on day and night. One had to wait for the next ESB bill to find there was a problem.

The items I want to record are:

- temperature

- humidity

- AC current

- CO2

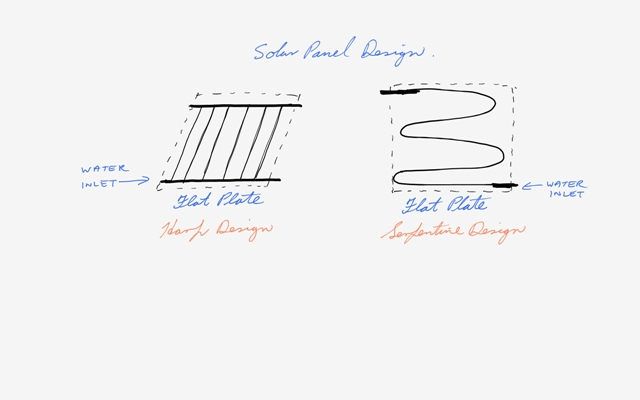

- Solar DC PV output

- Solar Hot Water inputs and Outputs

- Relay Outputs

I note that the american PHIUS (passive house breakaway group) which is the equivalent of the passive house institute in Germany have co-developed a building Monitoring solution starting at $800 with powerwisesystems.com . I feel this is still too expensive. Lets see what my research turns up.

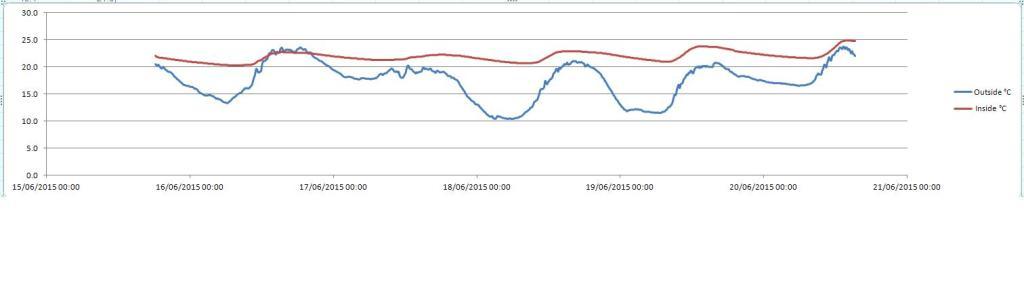

More Temperature Data (Update)

Inside and Outside Temperature with scaffolding taken down and all doors and windows closed-Image Below

Inside and Outside Temperature with scaffolding still in place-Image Below.

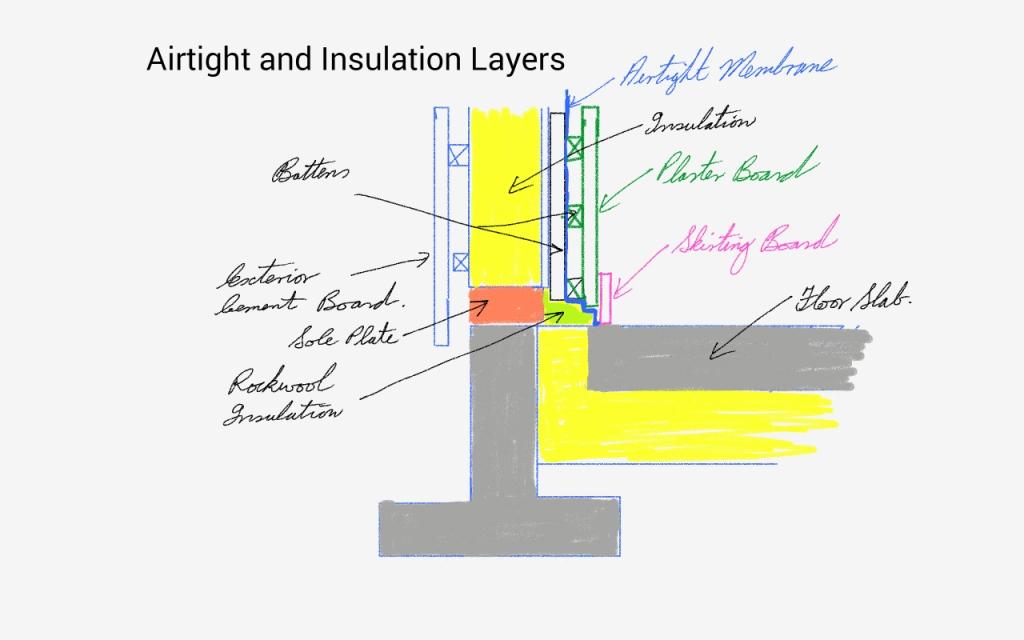

Wall Layers with Insulation

Wall Layers with Insulation