As part of the passive house requirement one needs to eliminate or minimise heat loss through linear lengths or points around the house. Some of the thermal bridges in my build are typical of other builds. I hope to provide more details in the future.

One of the main linear heat losses is with window/door installations (its connection with the wall frame ). It has been said numerous times that selecting a high quality window/door and installing it poorly can equate to buying a low energy window .

As mentioned before I will use the free software called Therm to calculate the losses. The first detail to tackle is the glazing which was directly mounted in the frame of the house without a window frame. These windows are 2.4 metres x .9 metre and there are 11 of these mounted on the south face.

The calculation of these linear losses can be expensive to get done so I will be doing the task myself and have it checked by others. I am surprised that good details are hard to come by on the web for free to help the self builder. One of the most time consuming exercises with thermal bridge calculations is drawing the detail. If one undertakes drawing this oneself using CAD (Computer Aided Design) software it can help to reduce the cost of the calculation.

When one needs to come up with a detail to minimise the losses there are a lot of products that help to keep the losses under control. These are semi-rigid insulation products like compacfoam, foamglass blocks, standard insulation, TECTEM, PU or rockwool and fibreglass products and aerogels (which is one of the highest performing insulators being made).

To date there appears to be very few online resources to guide the self builder or provide details that one can use before one starts a build.

Some background and details I found to date on thermal bridges can be found at the following links.

Scottish Thermal Bridge Details Link

Example of Heat Loss through a glass spacer

Below is an example of the thermal bridge calculations one needs to carry out to establish the thermal bridge performance values in W/(mk).

- One draws the detail as a DXF file using a drawing package (or draw the detail manually in Therm)

- Import the detail into Therm Software

- Add the technical details such as thermal conductivity of each item

- Tell Therm where on the drawing to stop the calculation (Adiabatic)-top and bottom of the drawing shown below.

- Tell Therm what the internal and external temperatures are

- Go to a spreadsheet and calculate the psi values of the thermal bridge detail for the passive house performance value.

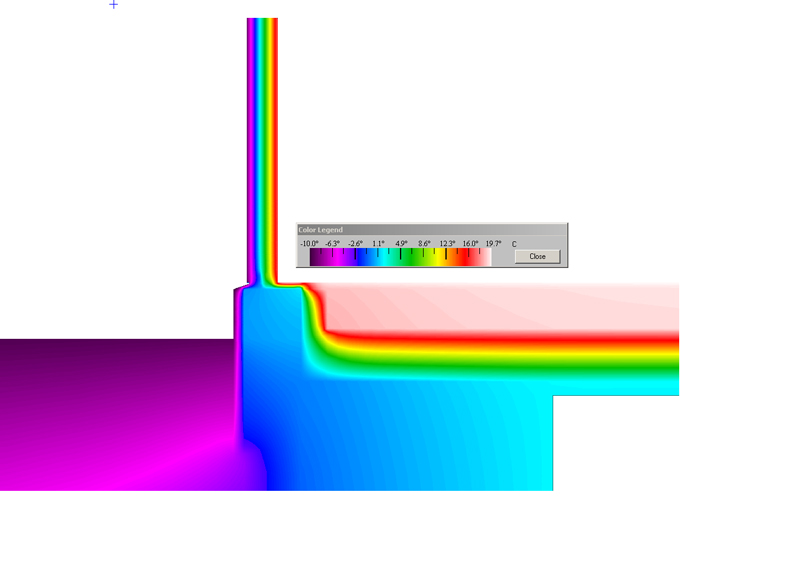

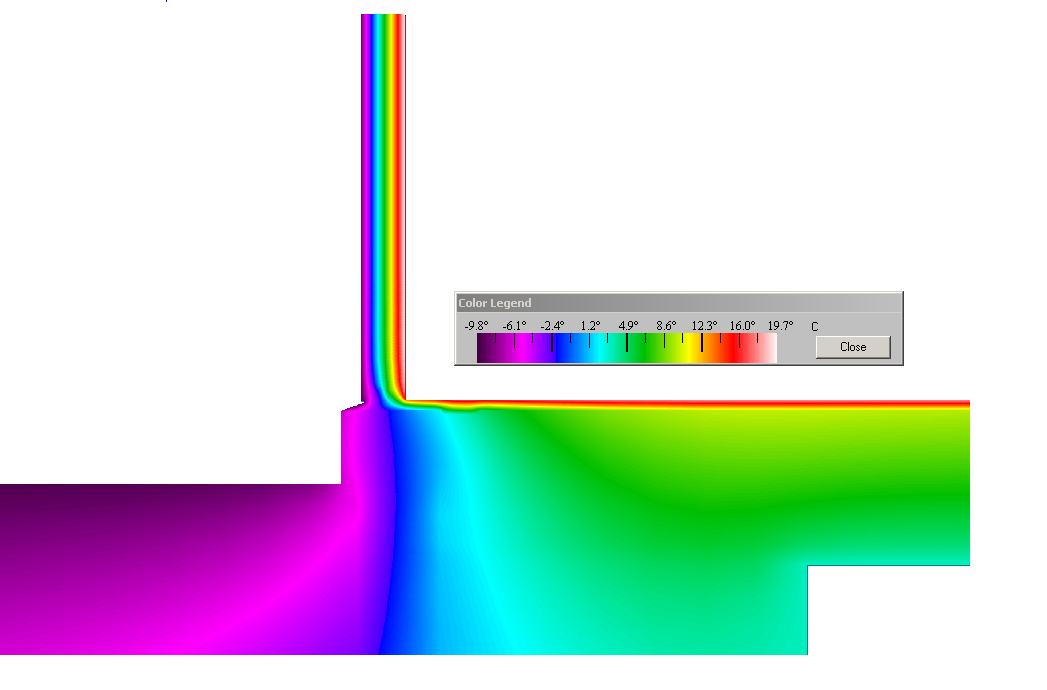

When this is done one ends up with the calculation and an image like that shown below. In this image the glass is shown near the top right.

In the next image the colours show the temperature gradients. The purple colour is the outside temperature at -10 degrees.

There is thermal bridge software that one can buy where the software calculates the psi value without using a spreadsheet but Therm is free and there are courses available in Ireland.

If one wants to show the real design and installation details of the thermal bridge values for the Irish regulations rather than the accredited details (without a performance value) one needs to use a certified thermal bridge accessors but this is not the case for the Passive House Institute.

We can all look forward to the day when standard construction details that are typically used in Ireland are already calculated for the self builder and there will be no need to pay to find out the thermal bridge losses . The Scottish accredited details (see above link) come close to taking the guess work out of construction.